SINGAPORE: A Nanyang Polytechnic (NYP) team has found a way to turn used coffee grounds into a flame retardant that could potentially be used to improve fire safety in homes and offices.

By treating coffee waste and mixing it with epoxy resin – a material commonly found in floorings and walls of homes – Dr Henry Leung and his team of three final-year students were able to leverage the slow-burning properties of coffee to create a material that could withstand a fire by as much as two times that of regular epoxy resin.

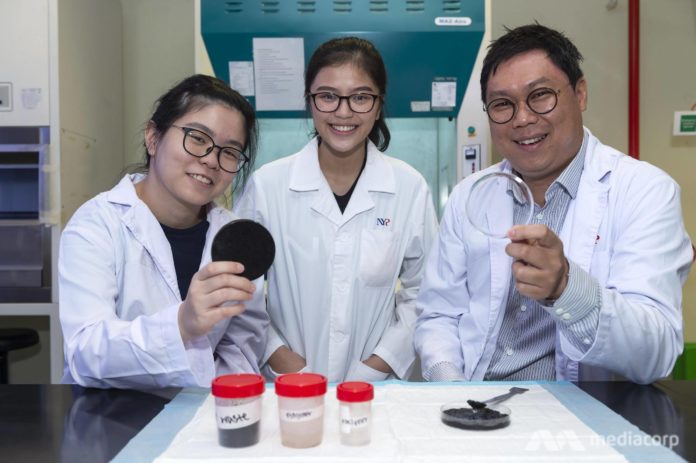

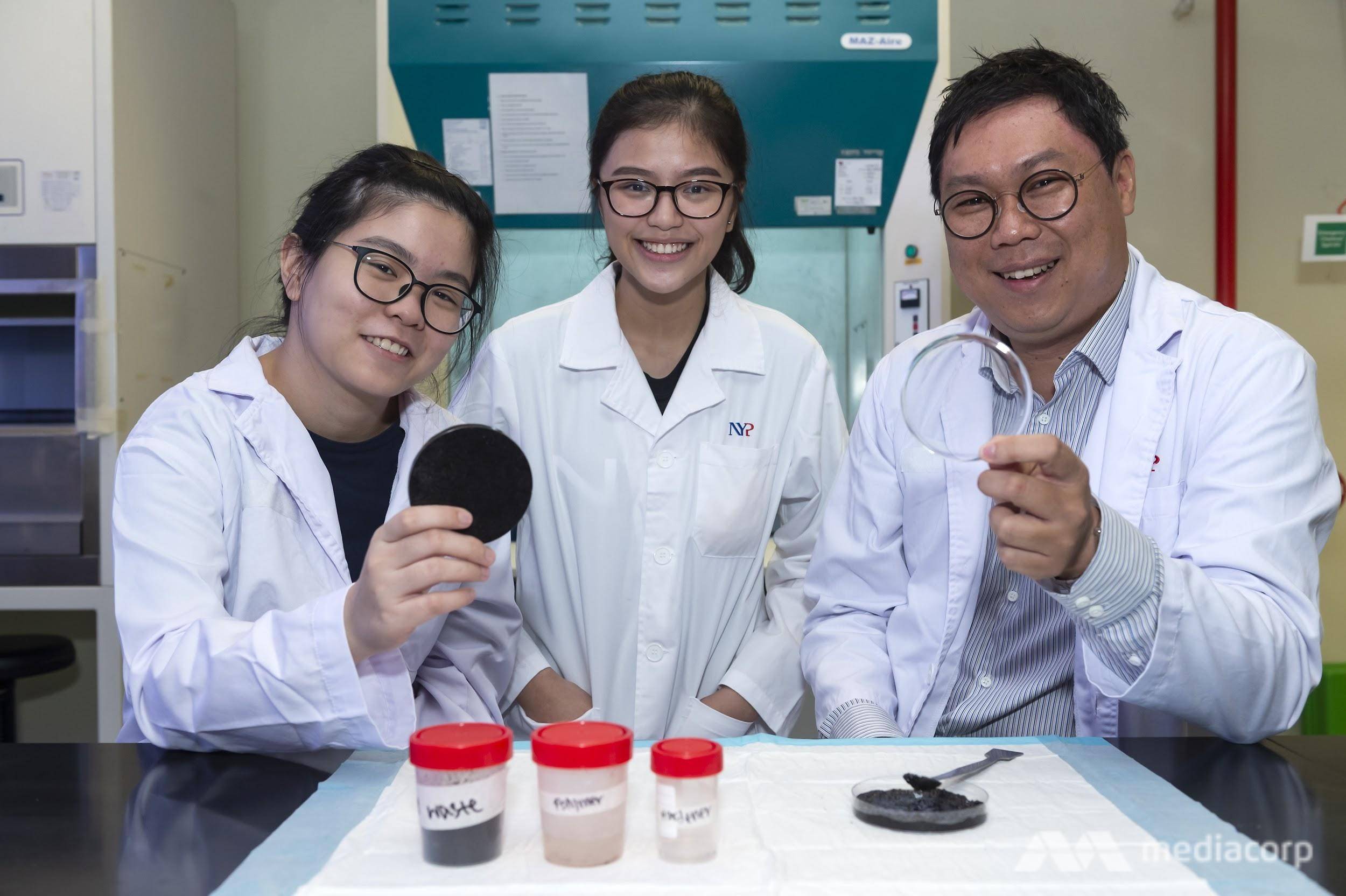

The Nanyang Polytechnic team that made a flame retardant from coffee waste: Dr Henry Leung (right), senior lecturer and senior specialist at NYP’s School of Chemical and Life Sciences, with two of the Diploma in Medicinal Chemistry students in his team, Shermaine Yeo and Yu Radyne Chale Castro. (Photo: Nanyang Polytechnic)

Regular epoxy is chemical resistant and highly durable – but despite its many advantages, it has poor resistance to fire and melts quickly, Dr Leung pointed out.

With coffee-epoxy resin, it would take a much longer time for the flames to spread, potentially improving fire safety in households and workplaces significantly, he said.

He and his team demonstrated the properties of their new coffee-epoxy material to journalists on Monday (Jan 14).

Student Shermaine Yeo clips on the coffee-epoxy resin sample carefully before igniting the burner for a test. The mixture of coffee waste and epoxy gives the sample its dark brown colour. (Photo: Alif Amsyar)

“After we did the first burning test with the coffee-epoxy resin and the results came out, I took a video and watched it many times, but I still couldn’t believe that the fire was put out,” Dr Leung quipped.

The 9mm-wide strip of coffee-epoxy resin burns at 18mm/min, well under the slow burning rate of 40mm/min. (Photo: Alif Amsyar)

The new material has also attained an “HB” grading, which indicates slow burning on a horizontal specimen, based on initial findings by a third-party testing laboratory.

Moving forward, the team is looking to further improve the material’s level of fire retardation, attain ISO certification and apply for international patenting, Dr Leung said.

“There are still a lot of ways that we can improve the current product – for example, by using nanotechnology on the coffee powder, which can create a more uniform density and advance the performance of the fire retardant.”

Dr Leung and his team spent roughly nine months to achieve the desired mixture with the best results – a specific ratio of epoxy (polymer), a chemical hardener and coffee waste. (Photo: Alif Amsyar)

Dr Leung added that apart from its fire-resistant qualities, the coffee-epoxy resin has the potential to become a total solution for reducing coffee waste.

Currently, grounding coffee waste into compost requires large storage space. The incineration of compost is also a space- and energy-consuming process.

Himself a coffee drinker, Dr Leung and his students are no strangers to turning coffee waste into sustainable products.

In 2017, the team also successfully created a biodegradable plastic from coffee waste.