SINGAPORE: A lensless camera that is capable of capturing sharp, coloured images could soon become a reality, with a new imaging technology developed by scientists from Nanyang Technological University (NTU).

It does away with the need for a lens and colour filters that are used in conventional cameras, and which are usually bulky and expensive due to the precision manufacturing required.

Instead, researchers have found a way to use a piece of ground glass and a monochrome sensor, then “reverse engineer” the light that is scattered by the surface of the glass using an algorithm to reconstruct the original image that was projected onto it, said NTU in a news release on Tuesday (Mar 13).

“By removing the need for a lens and colour filters and replacing them with ground glass, this innovation could potentially be applied to compact cameras and smart phones to make them slimmer,” NTU added.

The new technique is also cost-effective as it only requires a black and white camera coupled with a simple piece of ground glass, said assistant professor Steve Cuong Dang from the NTU School of Electrical and Electronic Engineering who led the research.

USING THE TECHNOLOGY FOR FOOD SAFETY TESTING

While researchers acknowledged that they still have years to go if they want to get images as sharp as those captured by commercial cameras, there are other potential uses in the more immediate future, such as food safety testing.

“For instance, it could be used for food safety, where one can take a photo of fruits or meat in particular spectra to look for spots that are associated with chemicals or bacterial activity leading to spoilage,” said Dr Sujit Kumar Sahoo, another member of the team.

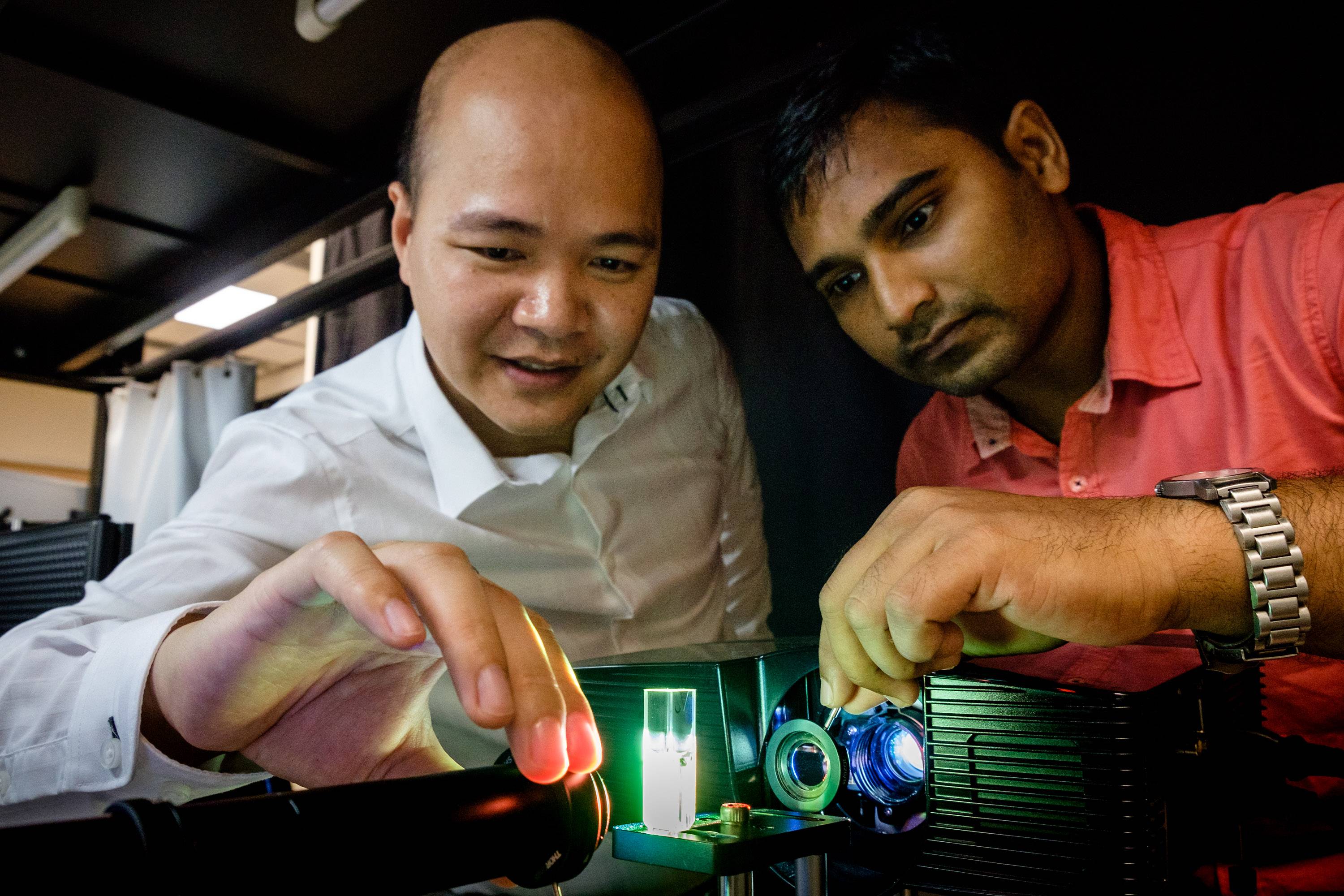

Assistant professor Steve Cuong Dang (left) with Dr Sujit Kumar Sahoo doing an experiment with the ground glass camera. (Photo: NTU)

Current technology can achieve this using a spectrometer, an apparatus that can split light into separate colours, but it is rarely used because it is expensive.

The cost of spectrometer can range between S$3,000 and more than S$40,000, said assistant professor Cuong Dang, adding that random samples from a batch of food products can be tested in a lab instead as a more cost-effective practice.

The researchers filed a patent for the new technology in July last year under NTU’s innovation and enterprise arm, NTUitive, and will be engaging industry partners to see how they can adapt their technology for real-world applications.

They added that they have received early interest from pharmaceutical companies which are already using similar technology for quality control, but are looking to lower such costs.