SINGAPORE: Scientists have developed a thin foam that could make buildings and vehicles cooler and quieter than if conventional insulation materials in the market were used, announced Nanyang Technological University (NTU) on Tuesday (Nov 22).

The new material – known as aerogel composites – is thinner than conventional foam “yet has better performance”, said NTU Associate Professor Sunil Chandrankant Joshi.

It is able to block out 80 per cent of outside noise, 30 per cent more than conventional insulation foams. The new material also insulates against heat 2.6 times better, according to NTU in a press release.

This also means less material is needed to achieve the same effect. For example, to reduce the noise generated by a moving truck to the level of a normal conversation, it would require a 25mm-thick common insulation foam, whereas only 15mm of the new material would be needed, explained NTU.

Insulation foams are commonly used in the interiors of building walls, vehicles, as well as oil and gas pipes for heat insulation and sound-proofing.

The new material is on 15mm thick (left), while common sound-proofing material is around 25mm thick (right). (Photo: NTU Singapore)

The aerogel composites took Assoc Prof Sunil and his former student Dr Mahesh Sachithanadam four years to develop. They said the material is also greener to manufacture, “as it does not require high heat treatment or toxic materials in its production.”

In addition, it is able to withstand high temperatures more than 1,000°C, allowing it to last up to eight years in environments such as those found in the oil and gas industry. Conventional insulation foams can last up to two years in such high-temperature environments.

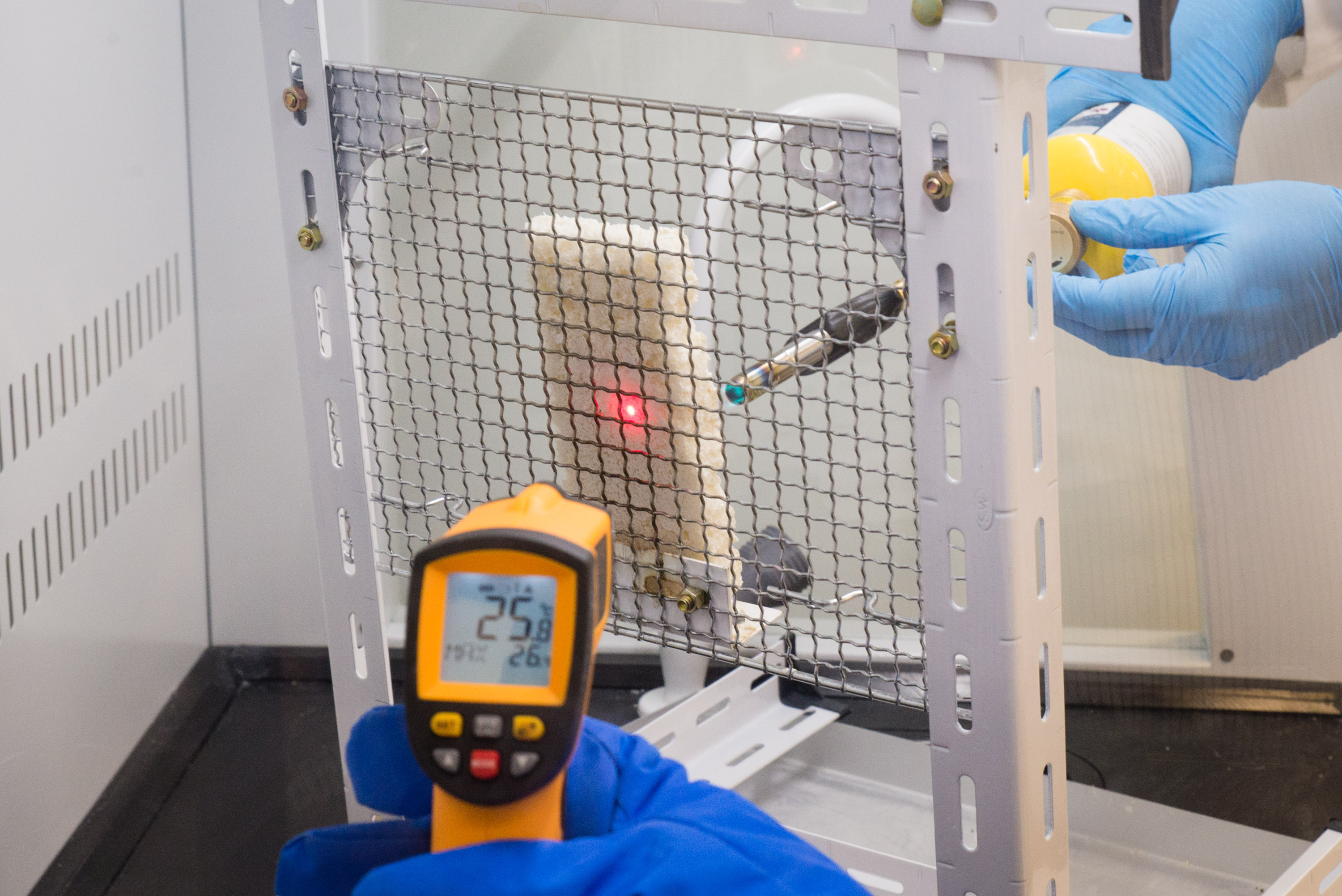

New thin foam subjected to 1,100°C flame while remaining cool at 26°C on the back. (Photo: NTU Singapore)

The new material is expected to hit the market by early 2017 when the production plant is operational.

In May this year, local company Bronx Creative & Design Center (BDC) licensed this aerogel composite technology with a joint venture of S$7 million. The plant will produce the aerogel composites for companies from the automotive, electronics, and oil and gas sectors.

“With global industries moving towards green manufacturing and a lowered carbon footprint, the new foam we produce will help address their needs and yet give a better performance,” the company said.