The maintenance of power

transformer is the daily work that

the electrician must do in order to keep the transformer in normal technical

condition and prolong its service life. Transformer maintenance is an important

part of electrical equipment management. If the maintenance work is done well,

not only can reduce the equipment failure rate, save maintenance costs, and

reduce costs. At the same time, it can bring good economic benefits to the

company. Today, OUGE will teach you how to maintain the power transformer in a

good way.

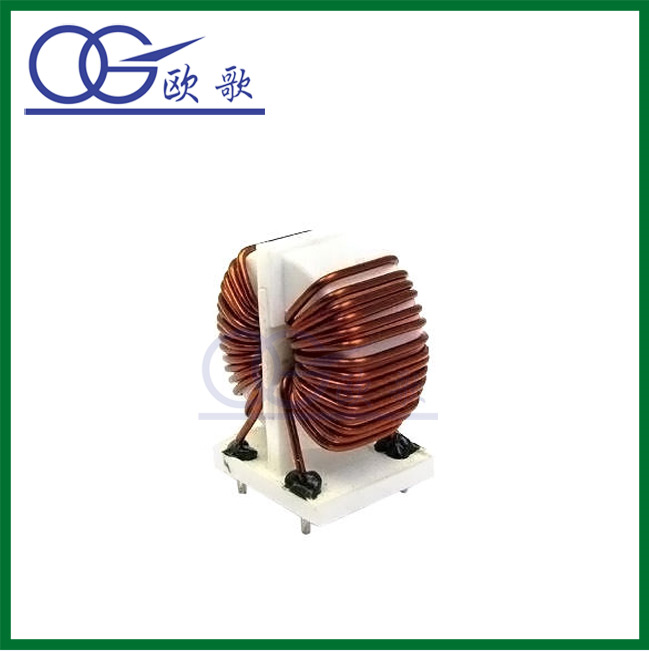

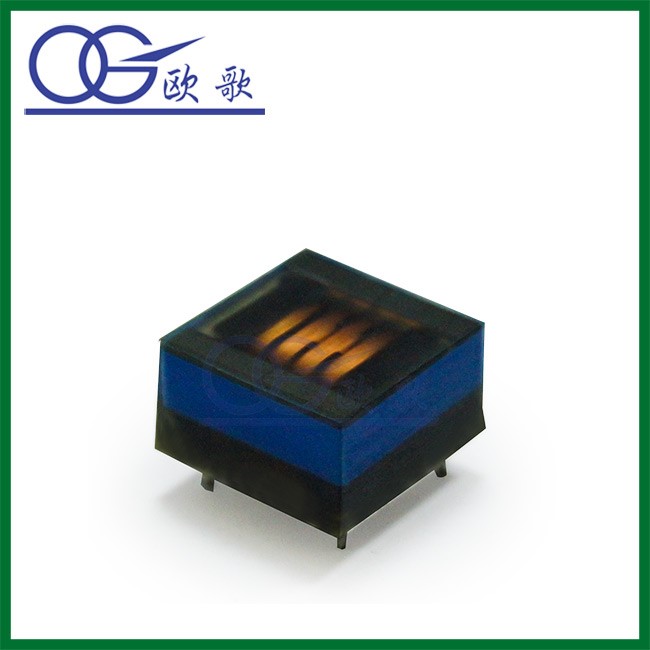

(

OUGE Electrical Transformer )

- Operate in the allowed temperature range

When the transformer is running, its coil

and iron core produce a copper loss and iron loss. These losses become heat

energy and make the transformer’s core and coil temperature rise. If the

temperature exceeds the allowable value for a long time, the insulation will

gradually lose its mechanical elasticity and the insulation will age.

The temperature of each part is different

when the transformer is running. The coil temperature is the highest, followed

by the core temperature, and the insulation oil temperature is lower than the

coil and core temperature. In addition, the upper oil temperature of the

transformer is higher than the lower oil temperature. The allowable temperature

in transformer operation is checked according to the upper oil temperature.

For A class insulated transformer in

normal operation, when the ambient air temperature is up to 400℃, the limit

operating temperature of the transformer winding is 1050℃. Since the temperature

of the winding is 100℃ higher than the oil temperature, in order to prevent the

deterioration of the oil, it is stipulated that the upper oil temperature of

the transformer shall not exceed 950℃. Under normal circumstances, in order to

prevent the insulation oil oxidation, the upper oil temperature should not

exceed 850℃. For transformers with forced oil circulation water cooling and air

cooling, upper oil temperature shall not exceed 750℃ frequently.

- Monitor the temperature difference between upper oil temperature and cooling air

Only monitoring the upper oil temperature

in the operation of the transformer can not guarantee the safe operation of the

transformer, but also must monitor the temperature difference between the upper

oil temperature and the cooling air. The difference between the transformer

temperature and the ambient air temperature is called the temperature rise. For

A class insulated transformer, when the maximum ambient temperature is 400℃,

the national standard stipulates that the temperature rise of the winding is

650℃, and the allowable temperature rise of the upper oil temperature is 550℃.

As long as the temperature rise of the transformer does not exceed the

specified value, it can ensure the safe operation of the transformer within the

specified operating life under the rated load.

In normal operation, the load of the

transformer should be about 75-90% of the rated capacity of the transformer.

The maximum unbalanced current at low voltage

shall not exceed 25% of the rated value, and the allowable range of transformer

supply voltage variation shall be plus or minus 5% of the rated voltage. If

this range is exceeded, tap switches shall be used to adjust the voltage to the

specified range. Normally, the tap position of the primary winding is changed

to realize voltage regulation. The device connecting and switching tap tap

position is called the tap switch, which adjusts the ratio by changing the

number of turns of the transformer’s high-voltage winding. Low voltage has no

effect on the transformer itself, only some output reduced, but it has an

effect on the electrical equipment.

The fault of the transformer can be

divided into an open circuit and short circuit. The open multimeter is easy to

detect, and the fault of short circuit cannot be detected by the multimeter.

- Short

circuit inspection of the power transformer

Cut off all the load of the transformer,

turn on the power supply, and see the no-load temperature rise of the

transformer. If the temperature rise is higher (hot), it must be an internal

partial short circuit.If the power is turned on for 15-30 minutes and the

temperature rises are normal, the transformer is normal.

First, a 1000 watt bulb is connected in

series in the transformer power circuit. When the power is on, the bulb only

turns red, indicating that the transformer is normal. If the bulb is very

bright or brighter, it indicates that there is a local short circuit in the

transformer.

- The

open circuit of the transformer

One is the internal coil break, but the

lead wire break is the most common, which should be carefully checked. If the

internal broken wire or the external can be seen to have burned traces, it can

only be replaced or rewound.

For more info, please visit:

http://www.ougedianzi.com/