Bulletproof glass has long been a critical component in military vehicles and aircraft, helping to shield their occupants from hostile fire in the battlefield.

But see-through ceramics – thinner, lighter and yet stronger – may soon take its place in Singapore’s arsenal.

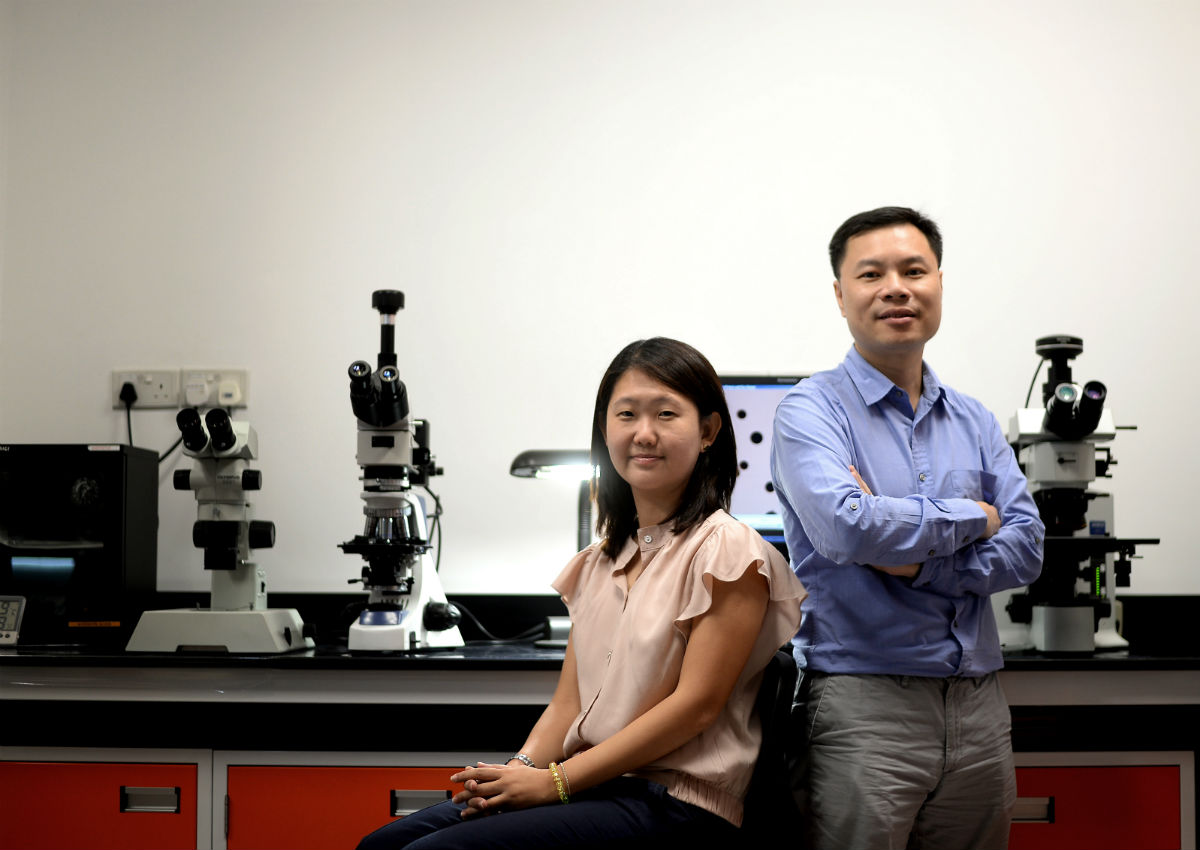

For five years, a pair of scientists toiled away in their “kitchen” in the Science Park at Kent Ridge.

Now, principal scientists Ang Seok Khim and Ernest Lau of Singapore’s DSO National Laboratories are seeing the fruits of their labour as the material goes into small-scale production while they wait for a patent to be granted.

These are the first steps towards actual use in military vehicles and other security applications such as civilian guardhouses and VIP cars.

The use of transparent ceramics will help Singapore reduce its reliance on other countries for cutting-edge defence technology, said DSO.

The two scientists’ endeavour started with a white powder – a secret ingredient – that is treated with a classified process that includes exposure to high pressure and temperatures exceeding 1,000 deg C.

This is needed to get rid of the microscopic defects that scatter light and prevent run-of-the-mill ceramic from being transparent.

The final product comprises tiny irregularly shaped crystals held together by strong chemical bonds.

The exact size of the crystals is a secret, too.

Ms Ang, 41, said: “It’s really (like) cooking… how you cut the vegetables, how long you want to cook, the temperature, how much pepper, salt and chilli.”

Like bulletproof glass, the transparent ceramic is laminated with plastic materials for actual use, but it is much harder than glass and works very differently.

While glass slows down a bullet through friction, the ceramic destroys it altogether.

First, the bullet fractures the ceramic into tiny pieces that have extremely sharp edges.

Mr Lau, 44, said: “You can picture it as millions of small little knifes.

As the bullet goes in, they shred it. This is really destroying the round (bullet).”

The ceramic, which is denser than glass, is so strong that it has to be only a tenth the thickness of glass to confer similar protection.

With the plastic lamination, the ceramic is about half the weight of bulletproof glass.

Mr Lau also explained that for a vehicle driver in the battlefield, bulletproof glass hit by bullets will shatter across a wide swathe of windscreen, preventing the driver from seeing outside.

“But for this material, the damage is so localised that… you can still see through the areas that are not hit. It means you can drive to safety.”

Other institutions here and around the world are developing transparent ceramics too.

Another institution here is Temasek Laboratories, which has facilities at three research universities in Singapore and is supported by the Ministry of Defence.

Professor Gan Chee Lip, director of Temasek Laboratories at Nanyang Technological University , explained that his institution explores the more basic properties of transparent ceramics while DSO’s work is more applied.

Prof Gan said DSO did a very good job, as a lot of engineering challenges had to be overcome to make such materials in larger sizes and quantities.

Farther afield, Germany’s IBD Deisenroth Engineering developed a similar ceramic in 2014 which it has introduced into armoured vehicles, while US company Surmet has come up with its own version, called Alon, in work funded by the US Department of Defence.

linyc@sph.com.sg

This article was first published on December 19, 2016.

Get a copy of The Straits Times or go to straitstimes.com for more stories.