SINGAPORE: A chemical company has been fined S$200,000 for a chlorine leak that exposed seven people to escaping chlorine gas, said the Ministry of Manpower (MOM) on Monday (Sep 24).

Following the leak, Chemical Industries (Far East) Limited pleaded guilty to a charge under the Workplace Safety and Health Act for “failing to take reasonably practicable measures” to ensure the safety and health of people involved in the company’s undertakings.

The incident took place on Sep 4, 2016 at Chemical Industries’ storage facility at Jalan Samulun where liquid chlorine leaked from a 1-tonne cylinder. The facility is on a small island off Tuas.

The leak triggered an alarm from a chlorine detector and a worker activated the chlorine gas emergency scrubber and exhaust system to regulate the ventilation.

Two workers then donned personal protective equipment and attempted to stop the leak, but were unsuccessful, said MOM. The Singapore Civil Defence Force (SCDF) was then called in and mitigated the leak.

READ: 7 sent to hospital after chlorine leak at industrial facility off Tuas

Two SCDF responders and five members of the public outside the facility were momentarily exposed to the leaked chlorine gas, and were later admitted to Ng Teng Fong hospital for treatment for issues like breathing difficulties and eye irritation.

They were discharged on the same day.

“MULTIPLE SAFETY BREACHES”

Multiple safety breaches were found following MOM’s investigations.

Firstly, the company had failed to maintain the fitted fastening on the container that controlled the pressure.

The fastening – called a fusible plug – was found to be “severely corroded”, said MOM, adding that it had resulted in the leak.

The company did not conduct any inspection of the fusible plugs during the external inspection of the containers before each filling, which would have revealed damage to the fusible plug, said MOM.

Photo showing the corroded fusible plug. (Photo: Ministry of Manpower)

In addition to that, MOM also found that the company failed to implement a detailed emergency response plan. The response plan that the company had in place assumed the chlorine would leak slowly as a gas instead of liquid under pressure – which was not the case during the Sep 4, 2016 incident.

To help contain the leak, the container had to be rolled over to position the leaking fusible plug at its topmost position, which would convert the liquid leak to a gas leak.

This would have reduced the rate of chlorine leaking out of the corroded connection significantly, allowing emergency responders to seal the corroded connection, preventing further leaks, MOM said.

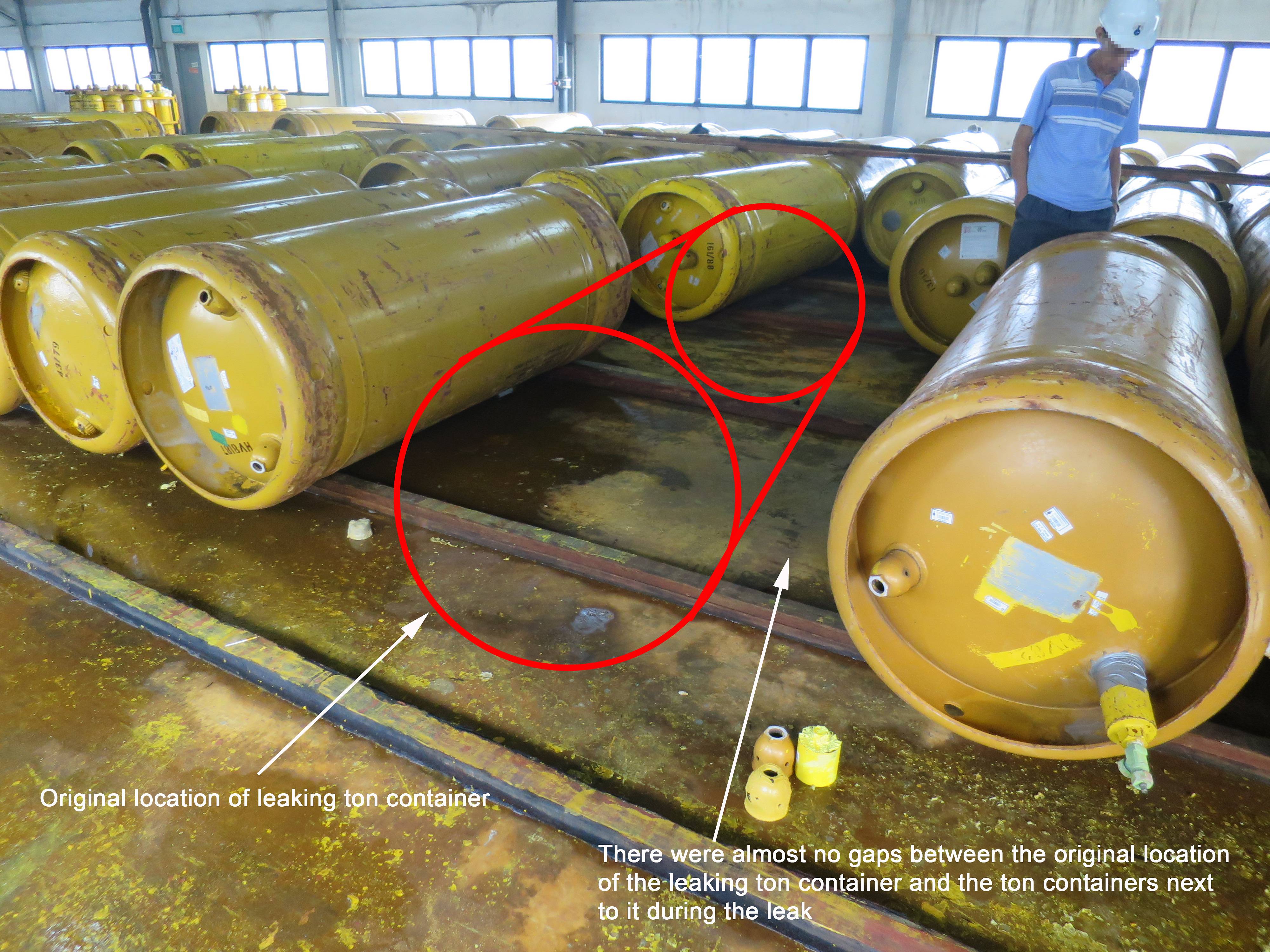

However, when the incident occurred, there was no space to execute this as the leaking container was stored between many other containers with no gaps.

Photo showing original location of leaking container. Container has been removed. (Photo: Ministry of Manpower)

The company had also failed to install its emergency scrubber and exhaust system according to design and maintain a safe ventilation in the workplace.

Some of the suction pipes within the warehouse used to extract air from the warehouse were found to be covered with mesh filters.

There were no calculations conducted to verify that these filters would not reduce the flow rate of air into the emergency scrubber and exhaust system, said MOM.

Photo showing mesh filter screen used on suction pipe intakes. (Photo: Ministry of Manpower)

“Investigations revealed that the rate at which the contaminated air was extracted did not meet general ventilation standards,” said MOM.

“The company had failed to properly maintain and store the ton containers, establish a proper emergency response plan to address chlorine leaks and implement an effective exhaust system for extracting and channelling contaminated air to the scrubber,” said MOM’s director of the major hazards department Go Heng Huat.

“The multiple safety breaches showed a clear disregard of the hazards at the workplace and had posed a safety risk to the public.”